About OEM/Partner Production Flow

We create our products from your point of view

As an OEM (Partner Production), our most important selling point is our ability to undertake production as a true partner to our customers. Since we are committed to delivering products that precisely meet our customer’s needs, we begin by placing ourselves in your position, so we can focus carefully on your requirements and intended uses for the end product. This uncompromising approach has enabled us to successfully deliver products for a wide variety of applications. When designing a mask, we carefully consider factors such as mask shape, pleating, and size. We also look closely at materials from a variety of perspectives. We have technologies and expertise that can turn your dreams into reality.

Ascertain customer’s requirements

Meeting

Product creation starts with carefully ascertaining customer needs.

The ideal product begins with confirming customer needs, whether for medical, dental, industrial, or home use.

Set specifications

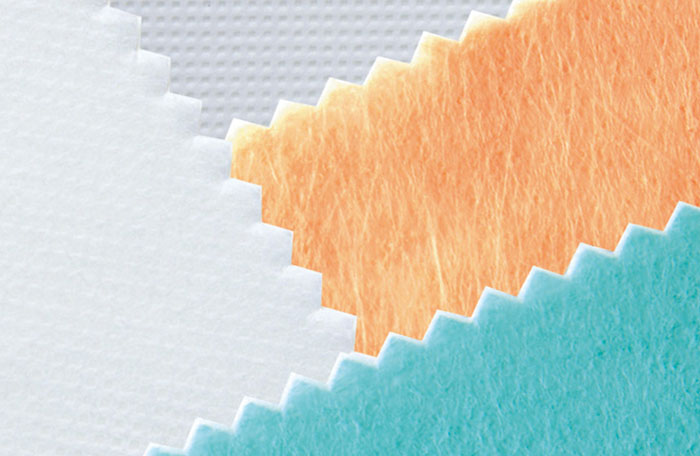

Sample Materials

Sample selection of materials best for the environment of intended use.

We select samples that best match the environment where products will be used.

Produce and evaluate samples

Brainstorming Session

Image of spetification

Determine specifications and create samples that meet customer requirements.

【Question】Is there a mask that guards not just the mouth but also the eyes against body fluids that spatter during surgery and medical treatment? 【Proposal】Fluid resistant mask with eye protector.

【Question】Is there a mask that can be worn for a prolonged period wthout making breathing uncomfortable? 【Proposal】Cup keeper mask

【Question】Is there an effective respirator that protects against tuberculosis, SARS, bird flu, and other such bacteria and viruses?

Do you have products that meet overseas standards (US, European, Australian, etc)? 【Proposal】N95、FFP1、FFP2、FFP3

Receive order

Plan production & order materials

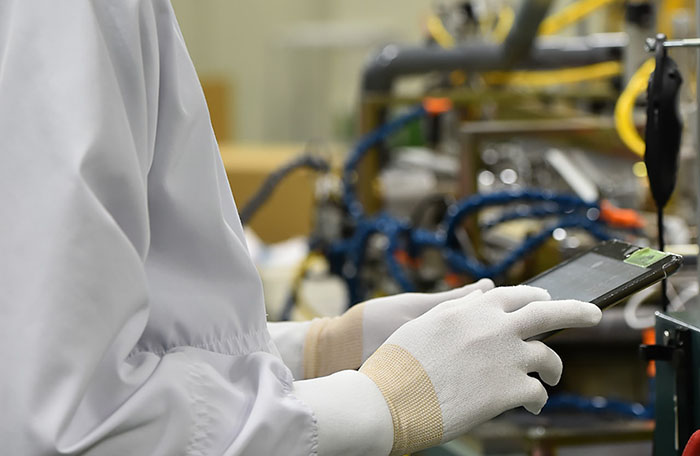

Controlled by digital devices

Producation Controll System

Production control from receiving order until distribution.

To maximize efficiency, we have a production control system in place. Production plan data allows us to automatically calculate the required quantity of raw material and make a viable purchasing schedule.

Materials Arrive & Pass Through Air Shower

Air Shower

The air shower removes dust and debris from materials.

Dust and debris are removed, not only from production staff, but also from raw materials before transportation to the production area to ensure a clean environment.

Patching

Process Image

Processing and patching technology for ultrasonic welding, etc.

We have developed our own facilities to ensure a stable production line. After bringing raw materials into the facility, all operations are fully automatic. Materials are untouched by human hands to ensure maximum hygiene.

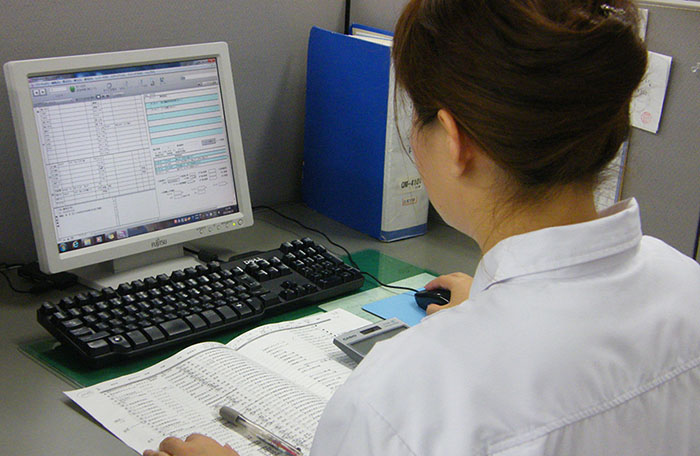

Quality inspection

Strength Inspection

Product quality check using CCD camera.

Inspection is accomplished by continuously using various sensors and CCD cameras to ensure high-quality and safe products.

Inspecting the filter efficiency

Sampling inspection using filter tester to confirm perfect quality.

The filter is the essential component of the mask. As the filter is invisible to the eye, the strictest quality control is necessary. We also spot-test to check if our products meet the customer’s precise needs. We then reconfirm quality through an outside testing organization.

Automated packaging

Process Image

Automated packaging of products in a clean environment.

Masks are packaged automatically in a clean environment and remain untouched until they reach the customers hands.

Deliver to customer

Product Release Process

Delivery when you want, where you want.

We can deliver our products anywhere in Japan the following day. We also ship worldwide.

Inquiry

We will propose products that align fully with your needs.

Samples can be provided upon request.

Please contact us if you have any inquiry.